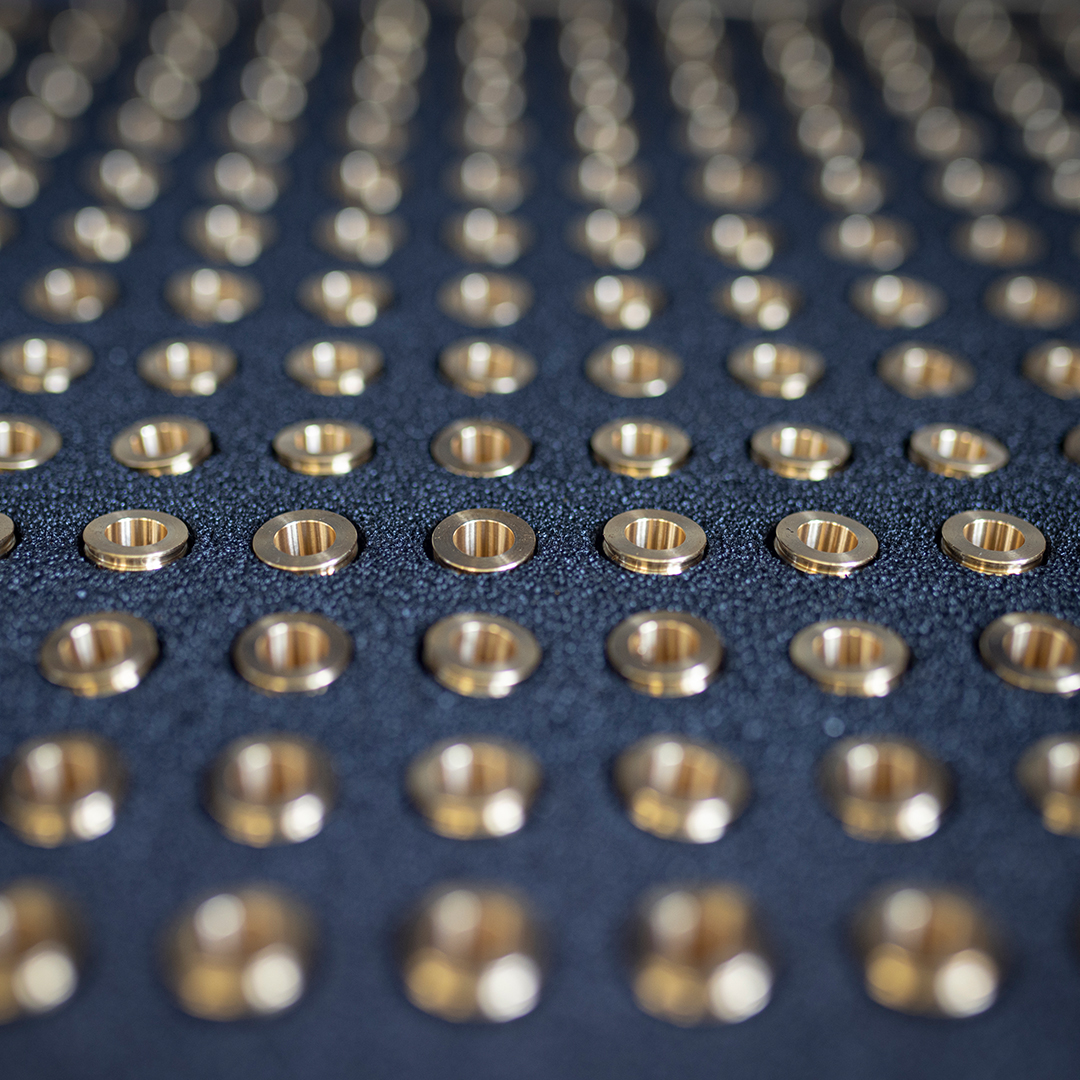

Turned parts ready for use from fibre material

Precision parts manufacturing since 1989

What does Instrum do?

– Processing from three-meter bar stock ranging from D3-22mm. Series production from 500 pieces up to several hundred thousand pieces.

– Manufacturing from D20-70mm bar stock, and from cut or pre-formed blanks up to D220mm, in quantities from 10 to several thousand pieces.

CNC longitudinal turning

CNC turning

Grinding

Finishing

Assembly

Where are our parts used?

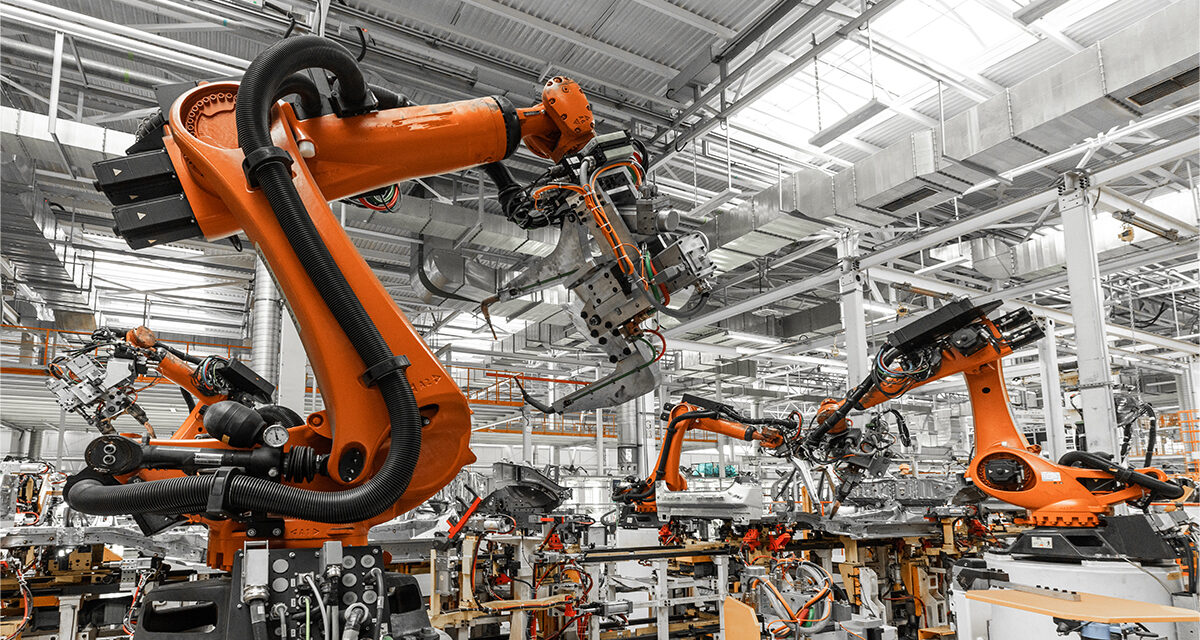

Automotive industry

Mechanical engineering

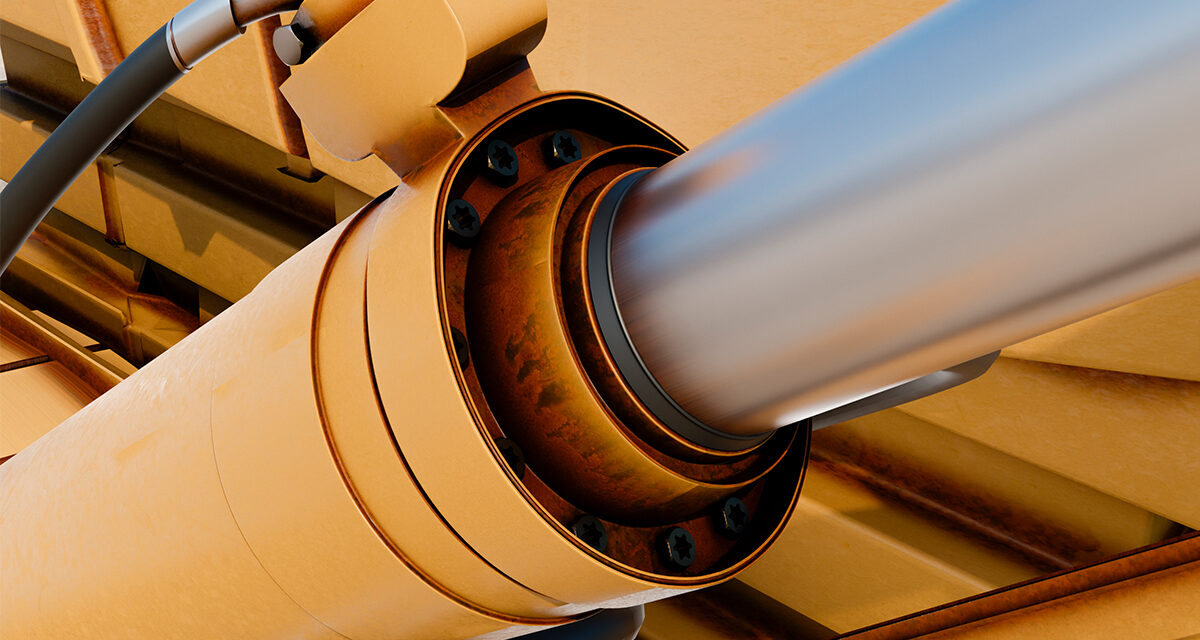

Hydraulics-pneumatics

Sealing technology

Contact us

Healthcare

Plastics and metal industry

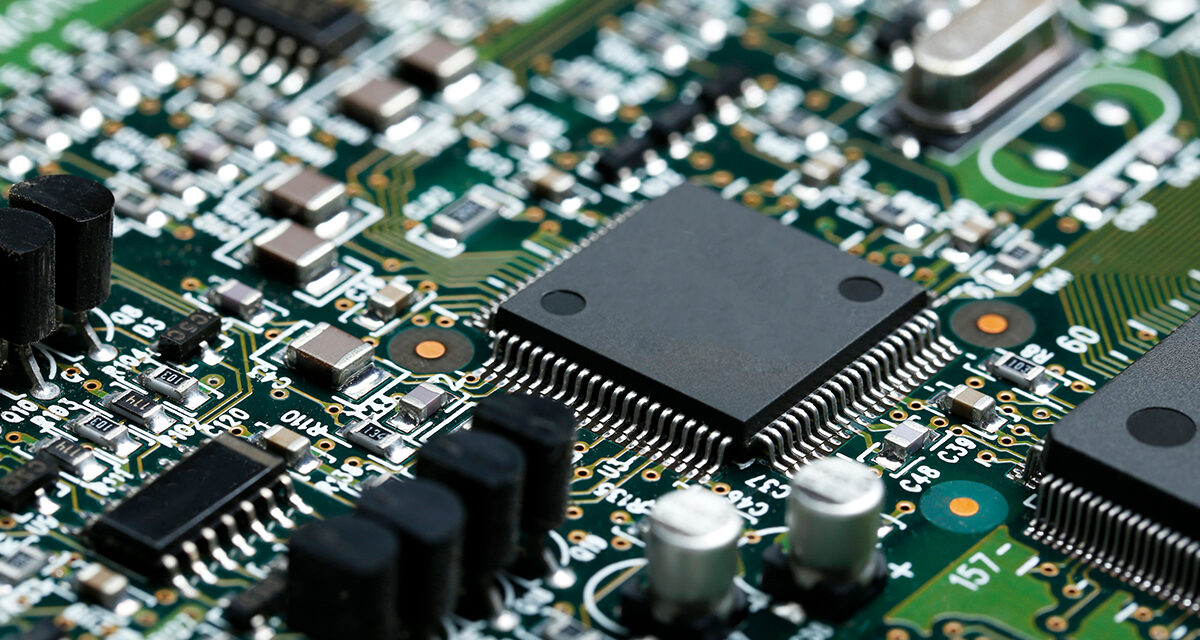

Electronics

Renewable energy

Our references

Find out more about Instrum’s expertise in CNC turning and parts manufacture

Instrum Ltd. mainly performs fibre metal machining by CNC turning, but grinding is also possible if required. We specialise in the production of small, high-quality precision parts. Off-the-shelf production can be done in small and medium series (from a few hundred to several hundred thousand pieces). Raw materials include steel, stainless steel, aluminium, red brass and brass. Our main profile is the machining of three-metre lengths of fibre material from 3mm to 22mm (CNC longitudinal turning). In case of CNC turning, we manufacture from fibre material up to 20mm-70mm, from chopped material – even from prefabricated material – up to 220mm. If necessary, precise finishing follows machining: threading, deburring, washing, packaging. If required, we can also assemble the parts. Our CNC machine park allows us to carry out plastic machining (industrial plastics – POM, PEEK), thus ensuring that we can provide a complete service to our customers.

We are proud to have a CNC turning plant that delivers not only to the cathcment area of Budapest and Hungary. The parts manufactured at Tököl serve the automotive industry, mechanical engineering, sealing technology and many other industries worldwide, including hydraulics (metal parts for control valves, such as piston pins and thermostat housings). The precision parts manufactured by Instrum Ltd. are used in the axles and brake systems of high-speed trains, in the lens housings of surgical magnifying glasses, but also in household appliances (boilers, turned liquid and steam pipes for coffee machines).

We believe that quality is not only guaranteed by Instrum’s more than 30 years of existence. The experience of our CNC-turning colleagues and the millions of parts we have produced are also a guarantee for our current and future customers. For any questions regarding turning, grinding and precision parts manufacturing, our professional team is available at any of our contact details: instrum@instrum.hu or +36 24 489 415.

On-time delivery

You can count on our proactive team!

30 years of experience